The Firm

Stemau S.r.l. was founded in Rome at the end of '80 years, producing and trading high quality wood floorings, turning to Firms and private Customers.

Thanks to our dedication, passion, the professionality, attention towards furnishing and design new tendency, cure in details, high quality, certificated and carefully selectioned raw materials, Stemau S.r.l. has always been a leader firm in this area. That is why we can satisfy all the personal, aestetical and ecomomical requirements.

Stemau S.r.l. makes wood into art.

Raw materials derive from all over the world, but the whole production cycle takes place in our Factory, based in Rome: starting from the cutting to the drying process, from the drawing to the project, from the choice to the section, from the calibration to the listels, from the planning to the working, from the varnishing to the packaging. That is why our goods is certificated 100% Made in Italy and all floors are CE marked.

We can realize several productions and finishing thanks to the copious wooden species available, the most innovative and modern machineries and our professionalit staff.

Not only Solid Wood Parquet, 2 Layers Prefinished Parquet, 3 Layers Floating Parquet, Outdoor Decking Parquet, we also realize Laminate Floor, LVT and SPC Floor and Outdoor Decking WPC.

To add value to luxurious and refined locations, Stemau S.r.l. produces prestigious handcrafted works as well chevron cut, steps, tiles, borders, mosaics, geometric wood tiles.

Stemau S.r.l. offers also consultant's advices and has several products for the lay down and maintanance of all floors (glues, primers, cements, impregnating, varnish and detergents), for furnishing complements (skirting boards and profiles) and for the merchandising (exhibitors and folders).

Parquet…the nature

In the building industry, timber represents an add value for houses, but also for shops, commercial areas, officies, hotels, gyms, theatres, restaurants and pubblic places.

A wooden floor is nature that lives, which gives warmith and comfort and which is daily whit us.

A wood flooring is a living nature. It daily enchances and gives us warmith and comfort.A wood flooring is welcoming, seductive, relaxing and it drives you to walk barefoot.

Enrich our places with wood flooring means to live in touch with the nature.

Stemau S.r.l. produces with the maximum respect for the nature. In fact we only use raw materials from firms and areas allowed to the deforestation, in order to properly support and protect the natural communities and the forests, following the very stricted standard rules.

The Factory

-

The Steps:

100% Made in Italy Production

- The parquet of Stemau S.r.l. was born after a

strict and careful selection of the best highly certified wood species.

Stemau S.r.l. produces a large range of wooden floors and it is a leader in the national market of Solid Wood Parquet and Prefinished Parquet. - 500.000 sqm produced in a year

- 1.000.000 sqm stored in warehouse

- Stemau S.r.l. produces the 100% of its sold Parquet

- The parquet of Stemau S.r.l. was born after a

strict and careful selection of the best highly certified wood species.

-

Production Cycle of

Solid Wood Parquet:

- Cutting of the elements

- Listels

- Drying Process

- Working

- Selection

- Packaging

-

Production Cycle of

2 Layers Prefinished Parquet:

- Cutting of the elements

- Listels

- Drying Process

- Cutting of the lamellas from 3 to 5 mm

- Gluing on the panels

- Calibration

- Varnishing

- Section

- Working

- Selection

- Packaging

-

Production Cycle of

3 Layers Floating Parquet:

- Cutting of the elements

- Listels

- Drying Process

- Cutting of the lamellas

- Gluing on the panels

- Calibration

- Possible colouring

- Varnishing

- Section

- Working

- Selection

- Packaging

-

Production Cycle of

Outdoor Decking Parquet:

- Cutting of the elements

- Listels

- Drying Process

- Working

- Selection

- Packaging

-

Production Cycle of

Outdoor Decking WPC:

- Cutting of the profile

- Working

- Packaging

-

Production Cycle of

Laminate Floor:

- Cutting of the panels

- Working

- Packaging

Our Structure

The factory

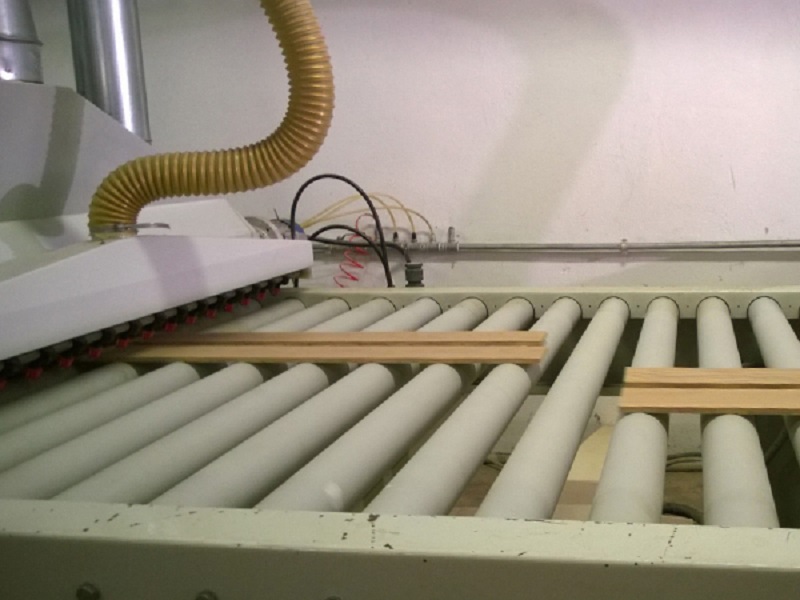

The Stemau S.r.l. production uses industrial modern and innovative machinaries, to guarantee the maximum quality of all products.

Warehouses

Stemau S.r.l. has 4 warehouses, to assure the faster delivery time.

Depliants and Exhibitions

Stemau S.r.l. is in the most well-known specialized magazines and it takes part to the biggest national and international exhibitions.

Stemau Point

Stemau S.r.l. dealers are located in several italian cities.

Our Staff

Stemau S.r.l. Staff is composed by qualified experts, who works with joy, passion, experience, professionality and ability.

Safe Wood System

Stemau S.r.l., thanks to its experience and professionality, patented a service called "Sistema Legno Sicuro". It means "Safe Wood System" as a matter of fact that we assist Customers to the choise of wood flooring and assure them the most professional lay down.

Sign up to our newsletter

to be informed about latest news and the special offers.